Revolutionising Taste

In today’s fast-paced beverage market, taste innovation is essential. Enter Flavours with Modifying Properties (FMPs), smart ingredients that do more than add flavour.

What we're talking about!

What we're talking about!

We’re strengthening our team

Read more

2025 – Trends, Innovations & Insights

Read more

See us at Drink Technology India

Read more

See us at Gulfood Manufacturing 2024

Read more

CO2Sustain vs. Traditional Carbonation Retention Methods

Read more

Less CO2 and more fizz

Read more

Beyond the Bubbles

Read more

Why longer-lasting fizz matters

Read more

Keeping the fizz alive

Read more

Retain the tingle and bite

Read more

Maximising beverage enjoyment

Read more

How CO2Sustain works

Read more

It’s all in the tingle and bite

Read more

Seeking a partner in North America

Read more

We’re approved in Brazil!

Read more

The ‘train set’ analogy

Read more

The Fizz Factor

Read more

Bold growth plans for 2024

Read more

Research & Development…

Read more

World Environment Day 2023

Read more

Keeping it Fizzy

Read more

Spring vibes

Read more

The challenges facing Cola manufacturers

Read more

CO2Sustain set to sparkle in North America in 2023

Read more

The dispense revolution

Read more

Energy savings

Read more

Extending shelf life

Read more

drinktec 2022

Read more

CO2 Lifeline

Read more

Plastic Packaging Tax is here

Read more

From wool to fizz

Read more

drinktec here we come

Read more

Plastic Free July

Read more

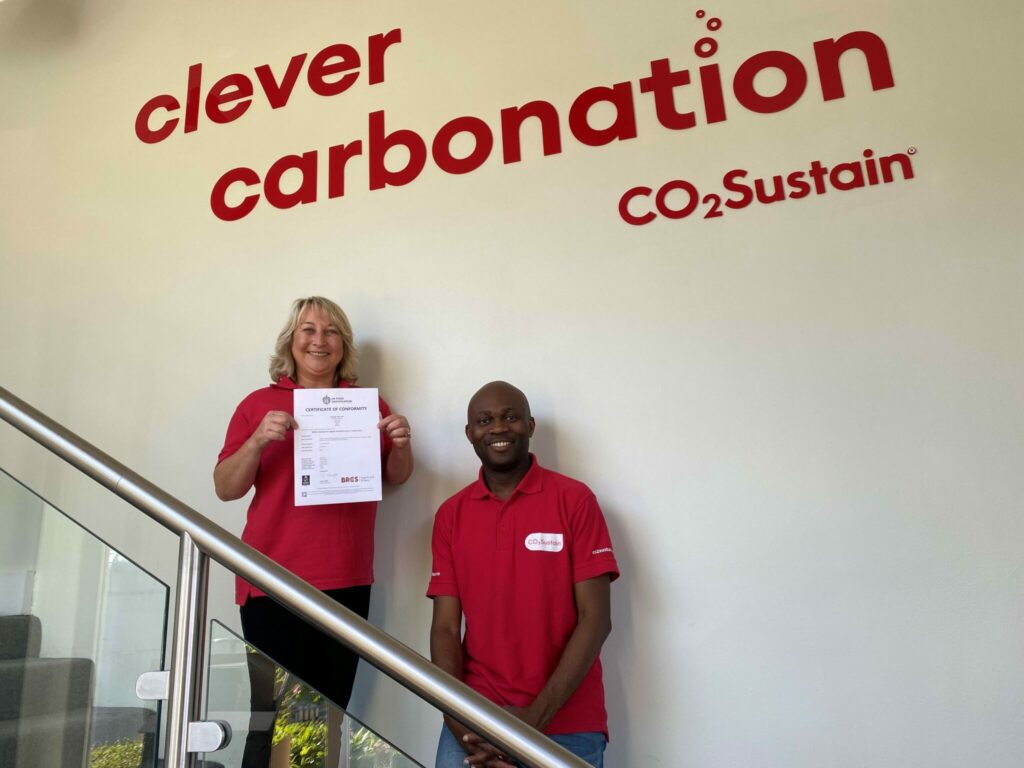

Grade A in our first BRCS Audit!

Read more

World Water Day

Read more

Recycle, recycle

Read more

A solution to CO2 shortages

Read more

Where are we now?

Read more

Yorkshire Manufacturer Partners With Industry Body

Read more

The Plastic Problem in the Beverage Industry

Read more

Fizz-retaining technology could reduce waste

Read more

African conference for Horsforth business

Read more

Global Success For CO2Sustain

Read more

The Doncaster business man who is changing the soft drinks sector

Read more

Yorkshire Manufacturing Business Prolongs The Fizz For Carbonated Soft Drinks Sector

Read more

The Very British Beverage – an ode to tonic

Read more

Innovative bubble technology prolongs fizz

Read more

Enhancing Carbonation Shelf Life

Read more

What’s the Fizz on the Zenith Global 2019 Soft Drink’s Conference?

Read more

Smaller bubbles – fizzier for longer

Read more

Putting more fizz into CSDs

Read more

What sets a beverage brand above the rest?

Read more

Understanding the soft drink industry

Read more

3 challenger brands making a splash in the CSD sector

Read more