Understanding the soft drink industry

Posted in Industry News

Constant innovation

We are constantly mentioning the different processes involved in the production of carbonated soft drinks, but it is important to understand the whole supply chain, from production all the way through to distributing to the consumer. In understanding how the process works, new beverage companies (or even old ones!) can find areas of opportunity to intervene and make their product better.

Commonly used terms

CSD (Carbonated Soft Drink): Traditional fizzy drinks, sodas or pop. The product needs to be carbonated. Excludes carbonated energy drinks or sports drinks.

Energy Drinks: Beverages that claim to awaken or provide alertness. Beverages that promote alertness and are marketed as a soft drink with added benefits.

Sports Drinks: Beverages that claim to rehydrate/replenish, as well as restore minerals, sugar and other nutrients lost during exercise.

The soft drink supply chain

Manufacturing soft drink is a multi-step process, and involves a number of steps before it reaches the consumer’s hand. Most soft drinks undergo a similar life cycle, beginning at the syrup producer, to bottler, to distributer (if necessary), to merchant and lastly, to final consumer. Each component is as important as the next in order to ensure the CSD is produced and packaged correctly.

Making bottled CSDs

CSDs usually vary in their recipe of syrup at the start of the manufacturing process. Raw materials such as flavourings, chemicals and sweeteners are mixed at different percentages to create a drink unique to the brand. Interestingly, around 94% of the soft drink is made up of carbonated water, thus making it a vital component of the drink.

The sweetener varies between non-caloric and non-diet soft drinks. Manufacturers will add a sugar substitute to the syrup concentrate for diet drinks, whereas for non-diet drinks, sugar is combined with the syrup at the bottling stage. When ready, proportioners combine the syrup and distilled water, and lastly the mixture is carbonated. Once completed, the drink is ready for packaging.

Controlling your carbonation

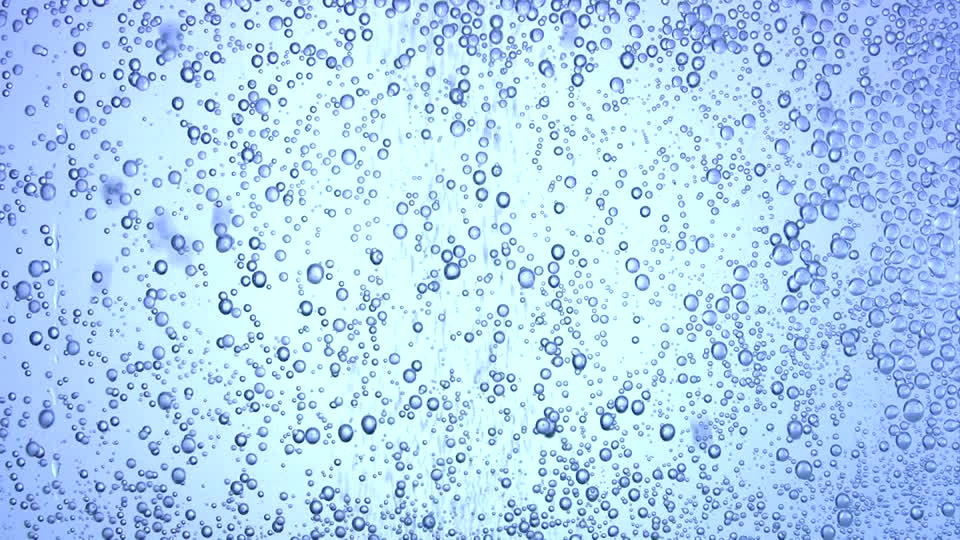

Foaming can cause a major problem for bottlers once the soft drink is carbonated. This can result in reduced line efficiency and slower start up times. For brands, it is important that each of the components in the manufacturing and bottling process runs smoothly so that they can adequately meet consumer demands whilst remaining profitable. This is where CO2Sustain® can help. This processing aid can be added at the time where the syrup and water are combined. When the mixture is carbonated, CO2Sustain® coats the CO2 bubbles, preventing them from merging into larger bubbles, resulting in reduced foam generation. This allows bottlers to increase the speed of bottling, and ultimately allow your CSD to be produced at a faster pace, reducing costs & saving you money!

For more information about CO2Sustain®, contact us here.

Resources

Public Health Law & Policy: A Guide To The Soft Drink Industry